* Bottle labelers enable the user to label all kinds of cylindrical objects.

* High accuracy and high apeed,dispensing & labeling automatically.

* The complete operation is PLC based.

* Can be widely used in various vertical round bottles. Suitable for small production.

* Label head stepper motor

* Emergency safety Off button

Specification

* Machine size:1270*100*78cm

* Output speed:20-200PCS/min

* Available bottle diameter:20-140mm

* Labe height:15-150mm

* Labe height:25-300mm

* Pastes the sign precision:+-1mm

* Label Inside diameter:76mm

* Label outside diameter:250mm

* Power supply:220V/110V 1KW 50/60HZ

* Weight:180kg

* Package size:1270*80*78cm

Tabletop Round Bottle Labeling Machine BJ-210T

Tabletop Round Bottle Labeling Machine BJ-210T

Tabletop Round Bottle Labeling Machine BJ-210T

Tabletop Round Bottle Labeling Machine BJ-210T

Payment & Delivery

* MOQ: 1 Unit

* Port: Shanghai

* Payment Terms: T/T, L/C, D/A, D/P, Western Union, MoneyGram, Paypal

* Packaging Material: Paper/Wood

* Packaging Type: Cartons

* Delivery: We’ll arrange delivery within 3 days on the receipt of payment.

We Provide

* Best products and factory price.

* On-time delivery and the shortest delivery time.

* 1-year warranty. If our products cannot function properly within 12 months, we’ll offer spare parts for free; and you need to pay for the delivery.

* OEM and customized service.

* User manuals will go with relative machines.

Service

* QC: All products will be checked before delivery.

* Compensation: If any unqualified product is found, we’ll pay the compensation or send new qualified products to customers.

* Maintenance & Repair: In case of any maintenance or repair need, we’ll help to find out the problem and offer relative guidance.

* Operation Guidance: If you have any problem with operation, please feel free to contact us.

Specifications:

* Voltage: AC200V/50Hz

* Power: 150w

* Label dimension: max: 120wx400l min:10wx30l

* Round bottle dimension: max: ?125mm. min: ?20mm

* Label inner core dimension: internal diameter: ?75mm; external diameter: ?300mm

* External dimension: 580x680x860mm

* Net weight: 45kg(including code machine)

Feature:

1. Adopt imported electromagnetic clutch with high accuracy

2. High-class aluminium alloy with long service life

3. Adopt the electric engine from the famous factory to make sure high load and long period of operation

4. All parts and standard components are made of stainless steel.

5. PLC control pane and LCD display the era sensation.

6. Imported label inspection optical coupler can ensure high precision.

7. It is applied to the labeling coding of round bottles like glass bottle, plastic bottle, can and so on.

Double-sided Round Bottle Labeling Machine (BJ-S130)

Payment & Delivery

* MOQ: 1 Unit

* Port: Shanghai

* Payment Terms: T/T, L/C, D/A, D/P, Western Union, MoneyGram, Paypal

* Packaging Material: Paper/Wood

* Packaging Type: Cartons

* Delivery: We’ll arrange delivery within 3 days on the receipt of payment.

We Provide

* Best products and factory price.

* On-time delivery and the shortest delivery time.

* 1-year warranty. If our products cannot function properly within 12 months, we’ll offer spare parts for free; and you need to pay for the delivery.

* OEM and customized service.

* User manuals will go with relative machines.

Service

* QC: All products will be checked before delivery.

* Compensation: If any unqualified product is found, we’ll pay the compensation or send new qualified products to customers.

* Maintenance & Repair: In case of any maintenance or repair need, we’ll help to find out the problem and offer relative guidance.

* Operation Guidance: If you have any problem with operation, please feel free to contact us

Specifications:

* Precision: ±1mm

* Label roll: Max:300mm

* Label core: Stander:75mm

* Machine size:2000x1300x1500mm

* Weight: 200kg

* Power: AC110V/220V 50/60Hz 500w

* Coding device: HP-260Q

Feature:

1.The machine is widely used in the fields of food, medicine, and fine chemical like oral liquid bottles, ampoule bottles.

2.Use motor to control and the touch screen of the human-machine-conversation type, which makes the operation easy and achieve high-speed and accurate labeling.

Double sides fully automatic labeling machine BJ-V300

Double sides fully automatic labeling machine BJ-V300Payment & Delivery

* MOQ: 1 Unit

* Port: Shanghai

* Payment Terms: T/T, L/C, D/A, D/P, Western Union, MoneyGram, Paypal

* Packaging Material: Paper/Wood

* Packaging Type: Cartons

* Delivery: We’ll arrange delivery within 3 days on the receipt of payment.

We Provide

* Best products and factory price.

* On-time delivery and the shortest delivery time.

* 1-year warranty. If our products cannot function properly within 12 months, we’ll offer spare parts for free; and you need to pay for the delivery.

* OEM and customized service.

* User manuals will go with relative machines.

Service

* QC: All products will be checked before delivery.

* Compensation: If any unqualified product is found, we’ll pay the compensation or send new qualified products to customers.

* Maintenance & Repair: In case of any maintenance or repair need, we’ll help to find out the problem and offer relative guidance.

* Operation Guidance: If you have any problem with operation, please feel free to contact us

Specifications

* Model: BJ-50

* Accuracy: ±0.5mm

* Speed: 25 – 50pcs per minute

* Available Bottle OD: 10 ~ 150mm

* Label Width: 8 ~ 150mm

* Label Length: 15 ~ 315mm

* Label Roll ID: 76mm

* Max. OD of Label Roll: 250mm

* Power Supply: 220/110V 50/60Hz

* Power Rating: 120W

* Dimension: 65×45×45cm

* Weight: 28Kg

Outside detail packing:

Feature

* Bottle labelers enable the user to label all kinds of cylindrical objects.

* High accuracy and high apeed,dispensing & labeling automatically.

Payment & Delivery

* MOQ: 1 Unit

* Port: Shanghai

* Payment Terms: T/T, L/C, D/A, D/P, Western Union, MoneyGram, Paypal

* Packaging Material: Paper/Wood

* Packaging Type: Cartons

* Delivery: We’ll arrange delivery within 3 days on the receipt of payment.

We Provide

* Best products and factory price.

* On-time delivery and the shortest delivery time.

* 1-year warranty. If our products cannot function properly within 12 months, we’ll offer spare parts for free; and you need to pay for the delivery.

* OEM and customized service.

* User manuals will go with relative machines.

Service

* QC: All products will be checked before delivery.

* Compensation: If any unqualified product is found, we’ll pay the compensation or send new qualified products to customers.

* Maintenance & Repair: In case of any maintenance or repair need, we’ll help to find out the problem and offer relative guidance.

* Operation Guidance: If you have any problem with operation, please feel free to contact us.

Related Round Bottle Labeling Machine

| Model | Available Bottle OD | Label Width | Label Length |

| BJ-50 | 10 ~ 150mm | 8 ~ 150mm | 15 ~ 315mm |

| BJ-70 | 10 ~ 150mm | 8 ~ 150mm | 15 ~ 315mm |

| BJ-80 | 10 ~ 150mm | 8 ~ 150mm | 15 ~ 210mm |

| BJ-90 | 10 ~ 150mm | 8 ~ 150mm | 15 ~ 210mm |

Specifications

* Model: BJ-70

* Accuracy: ±0.5mm

* Speed: 25 – 50pcs per minute

* Available Bottle OD: 10 ~ 150mm

* Label Width: 8 ~ 150mm

* Label Length: 15 ~ 315mm

* Label Roll ID: 76mm

* Max. OD of Label Roll: 250mm

* Power Supply: 220/110V 50/60Hz

* Power Rating: 120W

* Dimension: 65×45×45cm

* Weight: 28Kg

Feature

* Labelers enable the user to label all kinds of cylindrical objects.

* High accuracy and high speed, dispensing & labeling automatically.

Payment & Delivery

* MOQ: 1 Unit

* Port: Shanghai

* Payment Terms: T/T, L/C, D/A, D/P, Western Union, MoneyGram, Paypal

* Packaging Material: Paper/Wood

* Packaging Type: Cartons

* Delivery: We’ll arrange delivery within 3 days on the receipt of payment.

We Provide

Best products and factory price.

* On-time delivery and the shortest delivery time.

* 1-year warranty. If our products cannot function properly within 12 months, we’ll offer spare parts for free; and you need to pay for the delivery.

* OEM and customized service.

* User manuals will go with relative machines.

Service

* QC: All products will be checked before delivery.

* Compensation: If any unqualified product is found, we’ll pay the compensation or send new qualified products to customers.

* Maintenance & Repair: In case of any maintenance or repair need, we’ll help to find out the problem and offer relative guidance.

* Operation Guidance: If you have any problem with operation, please feel free to contact us.

Related Round Bottle Labeling Machine

| Model | Available Bottle OD | Label Width | Label Length |

| BJ-50 | 10 ~ 150mm | 8 ~ 150mm | 15 ~ 315mm |

| BJ-70 | 10 ~ 150mm | 8 ~ 150mm | 15 ~ 315mm |

| BJ-80 | 10 ~ 150mm | 8 ~ 150mm | 15 ~ 210mm |

| BJ-90 | 10 ~ 150mm | 8 ~ 150mm | 15 ~ 210mm |

Imported intelligent high-accuracy magic eye and high reliable Computer chip program controller(PLC)control the label and the case, label, using rubber roller pinned bottle the non-drying label followed the bottle in the bottle and put on rotating.

Advantages of product

1. Efficiency is as high as 50 times/minutes.

2. Labeling bottle adjustable, meet different before and after the workpiece labeling needs.

3. Labeling effect is good, no bubble, no creases, grade high, to increase product competitiveness.

4. Choose brand PLC and sensor etc electronic components, performance very stable.

5. Modular design, convenient maintenance and repair costs low.

Technical parameters

1. Voltage: 220V/50Hz / 110V/60Hz

2. Power: 150W

3. Label speed: 25-50pcs/M

4. Label accuracy: ?±1mm

5. Label Roll Inner Diameter: ≥Φ75mm

6. Max Label Roll Out diameter: ≤Φ250mm

7. Products size: Φ40mm-100mm

8. Wide of label: W150mm * L 180mm

9. Printer: None

10. Machine size: 70*60*55cm

11. Weight: 38kg

Operation sequence

1. First installation 2 slices of organic glass tray, respectively in two round installation fixed block, and then you will take slot first set of fixed block nursery dish core shaft, the green o-rings pull to fixed block of the trough, again fixed block screwed.

2. Label installation: the installation rolls label, is direction in clockwise tag along the label, and put the label on the tray to carry the external fixation and lock screw.

3. According to the label will wear the good direction, clockwise around the label head of standard, the bottom standard core clamping device and head out label, the clamp the clamping DaoBiao cylinder lock, otherwise the machine will not work. In the lock DaoBiao clamping cylinder, should pay attention to label the wheel about balance rubber balance rubber balance degree, such as no balance, can appear about labeling the phenomenon of up and down after label. The paragraph tags and bottom mark after must wear on the same level, and put all the film cylinder on the positioning of the circle, to ensure the proper position guide are tags.

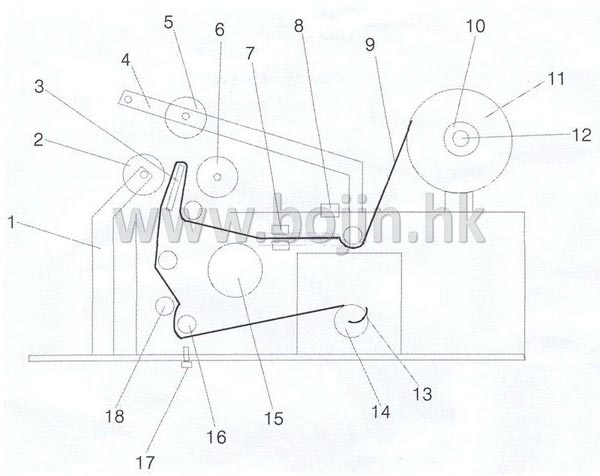

Machine diagram & Label stretching chart

| ?1 | ?Positioning arm | ?2 | ?Positioning roll |

| ?3 | ?Stripping plate | ?4 | ?Arm pressure bottle |

| ?5 | ?Rubber roller | ?6 | ?Rubber roller label balance |

| ?7 | ?Magic eye | ?8 | ?Start switch |

| ?9 | ?Label | ?10 | ?Fixed block |

| ?11 | ?Organic glass tray | ?12 | ?Tray pivot |

| ?13 | ?Waste paper clamping device | ?14 | ?Waste paper receiver |

| ?15 | ?Brake motors | ?16 | ?Clamping label guide wheel |

| ?17 | ?Paper feed adjustment screw | ?18 | ?Guide wheel |

4. The power supply plugged into the single-phase power supply (requires a good ground connection).

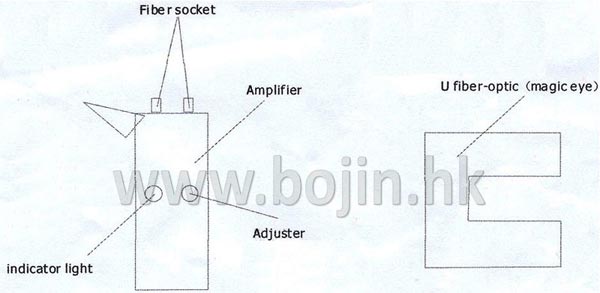

5. The power supply switch on, adjust the magic eye: Tag magic eye is by amplifier and U fiber-optic first two parts, As shown in Figure:

First will U fiber-optic lines of the head of arbitrary insert fiber socket2 centimeters, Then lock, Will regulator counterclockwise transferred to the lowest position, The tag through u-shaped fiber u-shaped slot, Two pieces of the label on fiber position of interval between head, Then the clockwise turn the regulator, Rotating slowly from low to high, Until light so far,

Back-and-forth pull Label, Label when on optical fiber head, indicator light off, Again, that signals a stable fine-tuning. These steps are completed, already successful commissioning that label magic eye. General before they have been tested.

a. Magic eye position: Magic eye position is related to label stopped position, so stay to adjust its position. Different sizes of label the required position is different also, Magic eye if position too back, will appear label is too long, Cause label head cannot adsorption label. Magic eye position quite rely on ahead, Will appear tags too short, Cause tags do not have labeling.

b. label stopped position: Is the index sign in labeling strip out before the length of Stripper plate, By magic eye to control. General adjustment to label head traps by tags just can.

6. Adjust the position of positioning arm: Positioning the bottle on the shelf is positioned to play on the rubber roller can rotate the role of, Depending on the diameter of the bottle, to adjust for the location of the bottle.

7. Pressing down the arm pressure bottle, press to start switch to work, pressure on the arm of the pressure bottle Pressing rubber wheel will rotate week

While rotating the bottle labels adsorbed on the bottle body.

Notice

1. Operators first before use, please be sure to read the instruction

2. Important: Do not locate the bottle of rubber rollers in the case above, there is no pressure bottle pressure arm, otherwise the work will switch to crush!!!

Troubleshooting

1. Labeling action is not normal: Check the label position is normal, Transmission mechanism have labels or foreign bodies stuck.

2. Label head don’t fall or not rise: Check whether normal and stable source.

3. Label do not adsorb: Check whether normal and stable source.

4. Label rolled up: Cheek whether the blowing tube correctly position.

5. Waste paper receiver don’t pull: Check whether the state tension membrane too tight.

Payment & Delivery

* MOQ: 1 Unit

* Port: Shanghai

* Payment Terms: T/T, L/C, D/A, D/P, Western Union, MoneyGram, Paypal

* Packaging Material: Paper/Wood

* Packaging Type: Cartons

* Delivery: We’ll arrange delivery within 3 days on the receipt of payment.

We Provide

* Best products and factory price.

* On-time delivery and the shortest delivery time.

* 1-year warranty. If our products cannot function properly within 12 months, we’ll offer spare parts for free; and you need to pay for the delivery.

* OEM and customized service.

* User manuals will go with relative machines.

Service

* QC: All products will be checked before delivery.

* Compensation: If any unqualified product is found, we’ll pay the compensation or send new qualified products to customers.

* Maintenance & Repair: In case of any maintenance or repair need, we’ll help to find out the problem and offer relative guidance.

* Operation Guidance: If you have any problem with operation, please feel free to contact us.

Related Round Bottle Labeling Machine

| Model | Available Bottle OD | Label Width | Label Length |

| BJ-50 | 10 ~ 150mm | 8 ~ 150mm | 15 ~ 315mm |

| BJ-70 | 10 ~ 150mm | 8 ~ 150mm | 15 ~ 315mm |

| BJ-80 | 10 ~ 150mm | 8 ~ 150mm | 15 ~ 210mm |

| BJ-90 | 10 ~ 150mm | 8 ~ 150mm | 15 ~ 210mm |

Working principle

Imported intelligent high-accuracy magic eye and high reliable Computer chip program controller(PLC)control the label and the case, label, using rubber roller pinned bottle the non-drying label followed the bottle in the bottle and put on rotating.

Features

1. Applicable scope, can meet 10-100 mm diameter range of cylindrical considerate scale

2. High accuracy of labeling, the acuities of label head to tail connect local just reache + / – 0.5 mm

3. The clever extrusion type device feeding, just need to place the pieces,it can automatically labeling

4. The jockey for position type adjustment, different workpiece labels switching simple

5. Adopt the synchronous belt traction, mechanical stability is greatly improved

6. Desktop design, the structure is simplified, appearance compact, powerful

7. Using the anodic oxidation of aluminium alloy stents and advanced computer white box, the beauty is generous

8. Using advanced electric eye, the object, the label high detection sensitivity.

9. Labeling and printing combined in one machine,it can print the production date,batch number,valid time and other words on each label accuratlly,and then label it on the round bottle.

Technical parameters

1. efficiency: ≤50pcs/min

2. precision: ±1mm

3. Applicable bottles of diameter: Φ10-150mm

4. Label roll: external diameter: 300mm inner diameter: 36-76mm

5. Label size: width 8-150mm length 15-210mm

6. Power supply: 220V, 50HZ 120W

7. Machine size: 650*450*450mm

8. Machine weight: 40kg

Outside detail packing:

Operation sequence

1. First installation 2 slices of organic glass tray, respectively in two round installation fixed block, and then you will take slot first set of fixed block nursery dish core shaft, the green o-rings pull to fixed block of the trough, again fixed block screwed.

2. Label installation: the installation rolls label, is direction in clockwise tag along the label, and put the label on the tray to carry the external fixation and lock screw.

3. According to the label will wear the good direction, clockwise around the label head of standard, the bottom standard core clamping device and head out label, the clamp the clamping DaoBiao cylinder lock, otherwise the machine will not work. In the lock DaoBiao clamping cylinder, should pay attention to label the wheel about balance rubber balance rubber balance degree, such as no balance, can appear about labeling the phenomenon of up and down after label. The paragraph tags and bottom mark after must wear on the same level, and put all the film cylinder on the positioning of the circle, to ensure the proper position guide are tags.

4. The power supply plugged into the single-phase power supply (requires a good ground connection).

5. The power supply switch on, adjust the magic eye: Tag magic eye is by amplifier and U fiber-optic first two parts, As shown in Figure:

First will U fiber-optic lines of the head of arbitrary insert fiber socket2 centimeters, Then lock, Will regulator counterclockwise transferred to the lowest position, The tag through u-shaped fiber u-shaped slot, Two pieces of the label on fiber position of interval between head, Then the clockwise turn the regulator, Rotating slowly from low to high, Until light so far,

Back-and-forth pull Label, Label when on optical fiber head, indicator light off, Again, that signals a stable fine-tuning. These steps are completed, already successful commissioning that label magic eye. General before they have been tested.

a. Magic eye position: Magic eye position is related to label stopped position, so stay to adjust its position. Different sizes of label the required position is different also, Magic eye if position too back, will appear label is too long, Cause label head cannot adsorption label. Magic eye position quite rely on ahead, Will appear tags too short, Cause tags do not have labeling.

b. label stopped position: Is the index sign in labeling strip out before the length of Stripper plate, By magic eye to control. General adjustment to label head traps by tags just can.

6. Adjust the position of positioning arm: Positioning the bottle on the shelf is positioned to play on the rubber roller can rotate the role of, Depending on the diameter of the bottle, to adjust for the location of the bottle.

7. Pressing down the arm pressure bottle, press to start switch to work, pressure on the arm of the pressure bottle Pressing rubber wheel will rotate week

While rotating the bottle labels adsorbed on the bottle body.

Notice

1. Operators first before use, please be sure to read the instruction

2. Important: Do not locate the bottle of rubber rollers in the case above, there is no pressure bottle pressure arm, otherwise the work will switch to crush!!!

Troubleshooting

1. Labeling action is not normal: Check the label position is normal, Transmission mechanism have labels or foreign bodies stuck.

2. Label head don’t fall or not rise: Check whether normal and stable source.

3. Label do not adsorb: Check whether normal and stable source.

4. Label rolled up: Cheek whether the blowing tube correctly position.

5. Waste paper receiver don’t pull: Check whether the state tension membrane too tight.

Payment & Delivery

* MOQ: 1 Unit

* Port: Shanghai

* Payment Terms: T/T, L/C, D/A, D/P, Western Union, MoneyGram, Paypal

* Packaging Material: Paper/Wood

* Packaging Type: Cartons

* Delivery: We’ll arrange delivery within 3 days on the receipt of payment.

We Provide

* Best products and factory price.

* On-time delivery and the shortest delivery time.

* 1-year warranty. If our products cannot function properly within 12 months, we’ll offer spare parts for free; and you need to pay for the delivery.

* OEM and customized service.

* User manuals will go with relative machines.

Service

* QC: All products will be checked before delivery.

* Compensation: If any unqualified product is found, we’ll pay the compensation or send new qualified products to customers.

* Maintenance & Repair: In case of any maintenance or repair need, we’ll help to find out the problem and offer relative guidance.

* Operation Guidance: If you have any problem with operation, please feel free to contact us.

Related Round Bottle Labeling Machine

| Model | Available Bottle OD | Label Width | Label Length |

| BJ-50 | 10 ~ 150mm | 8 ~ 150mm | 15 ~ 315mm |

| BJ-70 | 10 ~ 150mm | 8 ~ 150mm | 15 ~ 315mm |

| BJ-80 | 10 ~ 150mm | 8 ~ 150mm | 15 ~ 210mm |

| BJ-90 | 10 ~ 150mm | 8 ~ 150mm | 15 ~ 210mm |

Feature

* Bottle labelers enable the user to label all kinds of cylindrical objects.

* High accuracy and high apeed,dispensing & labeling automatically.

Specifications

* Model: BJ-210

* Drive way: Step by step motor

* Labeling Speed: 50-260pcs/min

* Avaiable volume area: Outside diameter 16-200mm, Height 35-200mm

* Available Label Size: Height 15-90mm, Length 23-300mm

* Accruracy: ± 1mm (according to the round bottle)

* Power: AC110V/220V 50/60HZ 500W

* Dismension: 1800X700X1270mm

Payment & Delivery

* MOQ: 1 Unit

* Port: Shanghai

* Payment Terms: T/T, L/C, D/A, D/P, Western Union, MoneyGram, Paypal

* Packaging Material: Paper/Wood

* Packaging Type: Cartons

* Delivery: We’ll arrange delivery within 3 days on the receipt of payment.

We Provide

* Best products and factory price.

* On-time delivery and the shortest delivery time.

* 1-year warranty. If our products cannot function properly within 12 months, we’ll offer spare parts for free; and you need to pay for the delivery.

* OEM and customized service.

* User manuals will go with relative machines.

Service

* QC: All products will be checked before delivery.

* Compensation: If any unqualified product is found, we’ll pay the compensation or send new qualified products to customers.

* Maintenance & Repair: In case of any maintenance or repair need, we’ll help to find out the problem and offer relative guidance.

* Operation Guidance: If you have any problem with operation, please feel free to contact us.

Related Round Bottle Labeling Machine

| Model | Available Bottle OD | Label Width | Label Length |

| BJ-50 | 10 ~ 150mm | 8 ~ 150mm | 15 ~ 315mm |

| BJ-70 | 10 ~ 150mm | 8 ~ 150mm | 15 ~ 315mm |

| BJ-80 | 10 ~ 150mm | 8 ~ 150mm | 15 ~ 210mm |

| BJ-90 | 10 ~ 150mm | 8 ~ 150mm | 15 ~ 210mm |

Data Sheet

First, the Basic uses:

Cylindrical objects can be used for a variety of thoughtful, such as xylitol, cosmetic bottles, etc, with a full week / Half week labeling, circular label on the back features; it can be equipped with semiautomatic ribbons fight code machine, printing machine, label print production lot number information.

Second, the scope of:

* Apply labels: self-adhesive labels, self-adhesive films, barcode, barcode, etc;

* Applicable products: request on a circular surface, cones attached label products;

* Application field: widely used in food, pharmaceutical, cosmetic, electronic, metal, plastics and other industries;

* Application examples: oral round bottle labeling, Xilin bottle labeling, labeling of xylitol, shampoo bottle labeling, small taper cosmetic labeling.

Third, technical parameters:

* Labeling accuracy: ±0.5mm ( does not contain products, labels, error );

* Labeling speed:10~30 pieces / minute (the theoretical value with product, label size and operational level);

* Overall dimension: 750x450x450mm(l x w x h);

* Available power source: 220V 50/60HZ;

* Weight: 32Kg

| Speed? | ?20~40pcs/minutes |

|---|---|

| Diameter(Round bottle) | ?Φ15mm~φ160mm |

| Label size? | ?Length:15mm~380mm;

Width:10mm~180mm |

| ID Roll | ?Φ76 mm |

| Outside diameter roll | ?Φ250 mm |

| Dimensions(L*W*H) | ??920mm*420mm*500mm |

| Power supply? | 220V, 50/60Hz |

| Power | ?200W |

| Weight | ?35Kg |

Equipment operating instructions

First part of solemn declaration

A. general matters

1. This labeling machine for the single stickers and double-sticker labels feature, you can manually switch. Specific reference to operations sections.

2. Labeling machine belonging to the non-standard equipment, its operation requires a certain amount of technical skill. Operation level, affects the efficient use of equipment.

3. Need to follow the instructions in the manual to operate the equipment, or carried out under the guidance of our technicians.

4. The technical manual is dedicated to the EP211 semi-automatic round bottle labeling machine (hereinafter referred to as labeler). Its purpose is to ensure that the professional use and adjustment of the equipment.

Second, the manufacturers permission

Company reserves the right to:

1. Body parts, electric components, as well as changes to software upgrades, also including parts of specifications and used the brand, to maintain the product’s advanced technology, but is not committed to deliver products free of change.

2. We have permission to device integrity protection, lack of factory technician under the direction of, not without permission to modify devices of mechanical or electrical parts, such as damage caused by violation of this provision by modifying party.

3. On the basis of this equipment, increase in ink-jet or other feature, we provide technical guidance on configuring, but don’t need to be responsible for supporting equipment.

4. Manual for this device and the operation of our company have intellectual property rights, such as copying, should bear the legal responsibility.

Third, security matters

1. Danger! Used to see to it that the ground to prevent electric shock.

2. Danger! Make sure the voltage is not overloaded.

3. Be alert! Electric box section, below the lines which need electrician to guide operational.

4. Be alert! Rotating parts requiring special attention to prevent pressure injury.

IV permission

? Ensure that only trained and those who have permission to operate, layout and maintenance of the equipment.

? Only allows qualified people, professionals, engineers and equipment to complete the layout.

Operate the machine need to ensure that:

–Security of individuals are capable of independent operation operation;

–Individual to your own fixing smaller errors that occur during the operation;

–Requires at least two people in the equipment used to guide;

Five, operating environment

Do not use in the following environments:

? Temperature changing competitive local

? Where high humidity and dew

? Places very strong vibrations or shocks

? Dust more places

? There is where the splash of water, oil, chemicals

? Where there are explosive, inflammable dangerous goods

Six, Break-in period

The labeler is within standard products, and have technical requirements for operators, you need to have a break-in period for a week or so. Run-in period, operation of equipment, technical parameters are reached, need to industry in a timely manner to reflect, to obtain technical support. Issues are essentially in the adjustment process can obtain information from this manual.

Payment & Delivery

* MOQ: 1 Unit

* Port: Shanghai

* Payment Terms: T/T, L/C, D/A, D/P, Western Union, MoneyGram, Paypal

* Packaging Material: Paper/Wood

* Packaging Type: Cartons

* Delivery: We’ll arrange delivery within 3 days on the receipt of payment.

We Provide

* Best products and factory price.

* On-time delivery and the shortest delivery time.

* 1-year warranty. If our products cannot function properly within 12 months, we’ll offer spare parts for free; and you need to pay for the delivery.

* OEM and customized service.

* User manuals will go with relative machines.

Service

* QC: All products will be checked before delivery.

* Compensation: If any unqualified product is found, we’ll pay the compensation or send new qualified products to customers.

* Maintenance & Repair: In case of any maintenance or repair need, we’ll help to find out the problem and offer relative guidance.

* Operation Guidance: If you have any problem with operation, please feel free to contact us.